8 Benefits of Using Rotary Encoders in Australian Mining and Port Operations

In Australian mining and port operations, rugged industrial components that offer speed and automation and are designed to work in harsh industrial environments are essential. Rotary encoders provide precise motion control, improved safety, enhanced automation, and efficient operations.

Rotary encoders serve as vital components used in cranes, conveyors, hoists, stackers, reclaimers, and drilling equipment, which are found in heavy industries. These high-precision systems offer accurate speed and position feedback, reduce equipment wear, minimise downtime, and support better load handling. This effectively improves the productivity and reliability of the industry.

Here, we’ll take a look at the primary benefits offered by rotary encoders in Australian mining and port operations.

What Are Rotary Encoders?

Rotary encoders are an electromechanical device that converts the angular position or motion of a shaft into analog or digital signals. It is used to measure rotation and is found in many applications, such as volume knobs, robotics, and industrial controls, to monitor or control a mechanical system’s position, speed, and direction.

These are used in various applications in mining trucks, conveyor belts, ship-to-shore cranes, and automated machinery.

High-precision encoder systems offer the following to heavy industries:

- Accuracy and precision control of industrial machinery

- Enhanced repeatability for conveyor lines

- Real-time feedback and system synchronization

- Safety and risk minimisation in safety-critical operations

- Elimination of cumulative errors

- Robust build and durability in harsh industrial conditions

Why Mining and Port Operations Need Precision

Mining and port operations involve high-value loads, intense operating conditions, and strict safety requirements. Further, they also face industrial extremes like dust, temperature extremes, vibration, and continuous operation. As a result, these industrial operations need precision equipment like rotary encoders that are designed to perform reliably.

The key applications of high-precision rotary encoders in Australian heavy industries are:

| Equipment Type | Mining Application | Port Application | Encoder Benefit |

| Conveyors | Ore transport | Bulk cargo handling | Speed and position control |

| Cranes | Draglines and hoists | Ship-to-shore cranes | Accurate load positioning |

| Drills and Excavators | Precision drilling | — | Vibration-resistant motion control |

| Stackers and Reclaimers | Stockyard control | Cargo distribution | Smooth automated movements |

Table 1: Industrial equipment and how they benefit from rotary encoders

Benefits Offered by Rotary Encoders

In Australian mining and port operations, rotary encoders offer the following benefits:

1. Enhanced Accuracy and Precision

Using high-precision encoders ensures accurate speed and position measurement, which is critical for crane hoisting, conveyor belt regulation, and drill control. This helps reduce costly errors in load handling and equipment alignment in heavy industries.

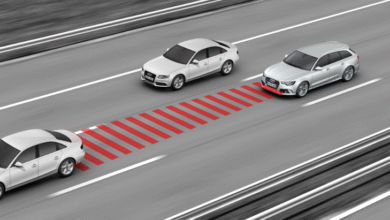

2. Improved Safety for Workers and Machinery

Industries pose multiple hazards like crane collisions, unsafe load swings, and conveyor overloads that may require emergency stop responses. To ensure worker and industrial safety, rotary encoders prevent over-travel, overload, and misalignment of key industrial machinery.

3. Increased Equipment Lifespan

The precise feedback from rotary encoders can reduce mechanical strain and wear in machinery. This leads to smooth operations and fewer breakdowns in high-impact environments. The result is longer service life for motors, gears, drives, and rotational components.

4. Reduced Downtime and Maintenance Costs

Early detection of motion anomalies through encoder data can minimise unplanned shutdowns in mines and container terminals. Thus, it supports predictive maintenance strategies, helping Australian mining and port operations take preemptive measures.

5. Better Automation and System Integration

Rotary Encoders for Australian industries are built for integration with PLCs, SCADA, and autonomous systems. These are essential for automated stackers, reclaimers, and robotic ore loaders. Further, they are also compatible with the Industry 4.0 initiatives being made by Australian industries.

6. Increased Productivity and Throughput

The use of rotary encoders can improve cycle times for ship-to-shore cranes and conveyor lines. Further, they also offer consistent speed regulation that helps achieve maximum material flow. This boosts output in both mining processing plants and port terminals.

7. Enhanced Reliability in Harsh Environments

IP-rated encoders are resistant to dust, water, shock, and vibration. Thus, they are built to withstand extreme heat in Australian mining sites and corrosion risks in coastal ports. Further, custom housings and sealing options are available from Rotary Encoders Australia suppliers can increase the life of the devices when working in harsh industrial environments.

8. Versatility Across Multiple Industrial Applications

High-precision encoders are suitable for cranes, drills, vehicles, elevators, and conveyors. Thus, they work well with both new equipment and system retrofits, and support diverse operations across Australia’s mining and port sectors.

See also: SFM Vompile: Advanced Techniques for Animation Mastery

Comparing Encoder Types: Which Is Right for Australian Heavy Industries

When choosing rotary encoders for Australian industries, the factors to consider include accuracy level, environment, vibration, speed, load, and safety needs. Based on their types, high-precision rotary encoders offer the following:

| Encoder Type | Best For | Key Strengths | Typical Use |

| Incremental | General motion control | Cost-effective, simple | Conveyors, smaller cranes |

| Absolute (Single-Turn) | Precise positioning | High accuracy | Hoisting, drilling |

| Absolute (Multi-Turn) | Complex automation | Retains position after power loss | Port cranes, stacker/reclaimers |

| Magnetic Encoders | Harsh environments | Vibration and dust resistance | Mining equipment |

| Optical Encoders | High precision | Clean, controlled environments | Processing plants |

Table 2: Comparison of encoder types

ROI of Using High-Precision Encoders

The use of high-precision encoders can lead to reduced maintenance costs, lower replacement frequency, and increased uptime and productivity.

A tabular summary of the ROIs is as follows:

| Benefit Area | Estimated Improvement | Financial Impact |

| Equipment lifespan | +20–35% | Lower replacement cost |

| Maintenance costs | –15–25% | Fewer repair hours |

| Uptime | +10–18% | Higher throughput |

| Safety incidents | –20–30% | Lower insurance and downtime |

| Productivity | +12–20% | Faster cycles, more output |

In Conclusion

The productivity of Australian heavy industries is dependent on the accuracy of the equipment used. The use of high-quality, high-precision Encoder systems in heavy industries is crucial for enhancing safety, accuracy, and productivity, as well as managing high operational demands.

Improving Efficiency with Rotary Encoders

Ready to reduce downtime and increase productivity? Explore reliable rotary encoder solutions or request an equipment consultation to improve your operational efficiency.